按鍵

HONLEX has been specializing in the production of membrane switches and thin film keyboards for over 30 years, and we have the capability to meet diverse customer needs.

To complete the tasks assigned by our clients, we have various processes and equipment, including screen printing machines, color separators, hot press machines, punching machines, laser cutting machines, automatic punching machines, adhesive machines, and clean rooms. We also have a wide range of equipment for reliability and environmental testing.

Thin film keyboards can be used in industrial human-machine interfaces, household appliances, medical equipment, aviation, military and any product that requires keyboard use.

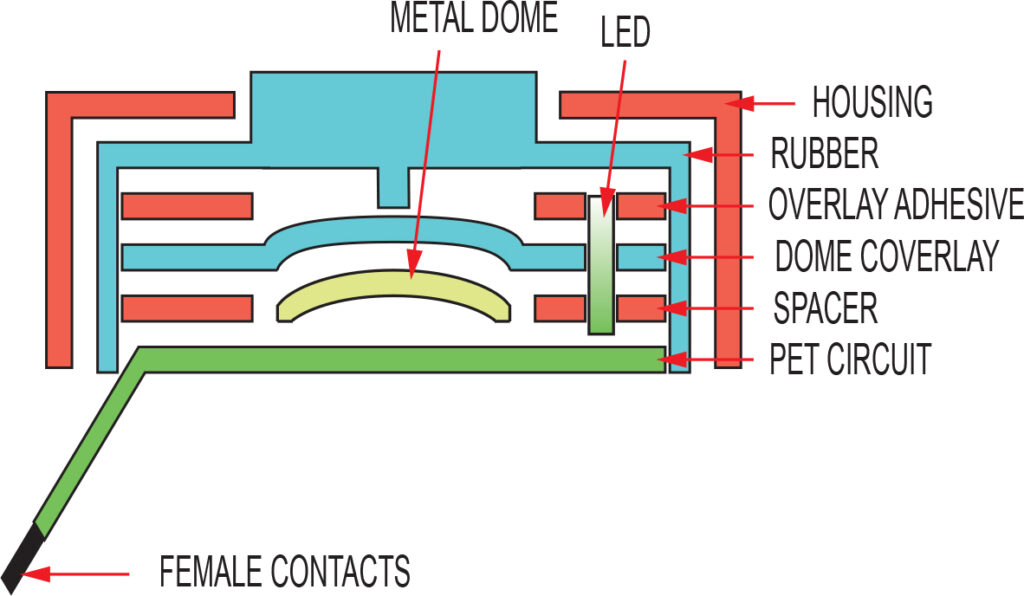

STRUCTURE OF MEMBRANE SWITCH

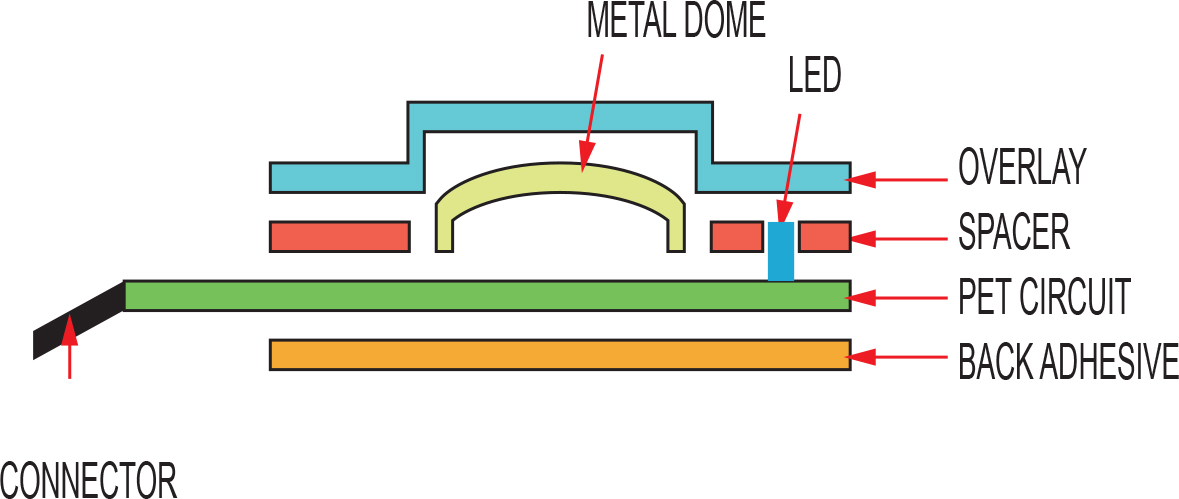

MEMBRANE SWITCH WITH BACK LIGHT

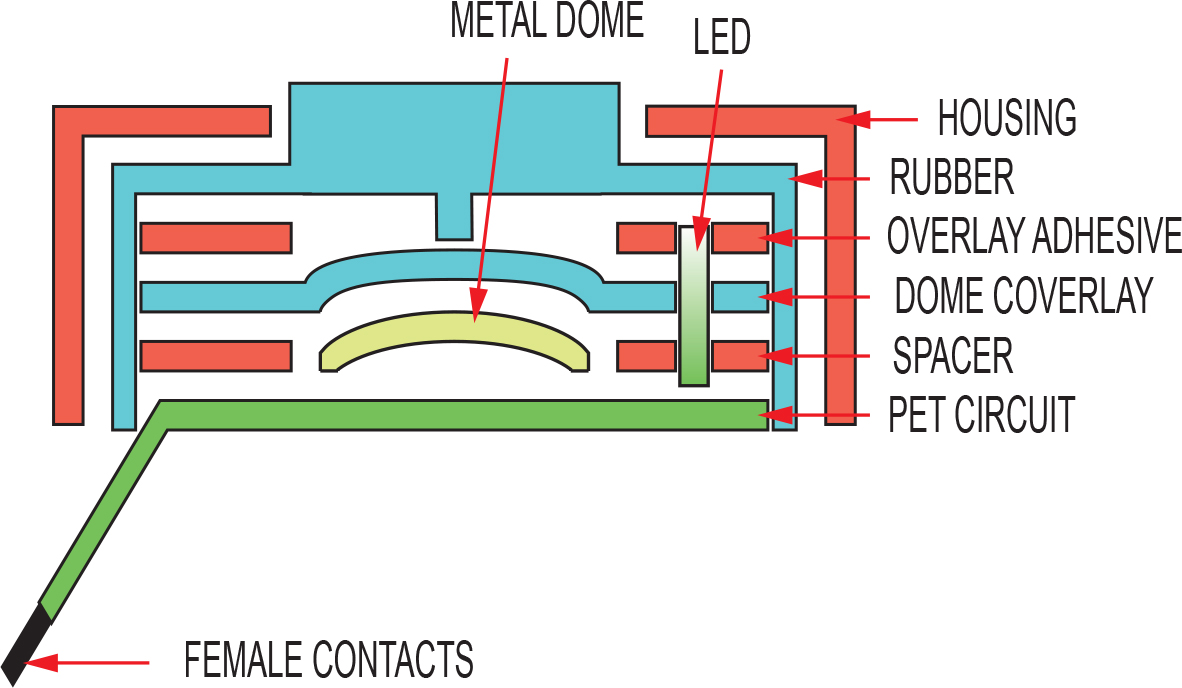

MEMBRANE SWITCH WITH RUBBER TOP

MD P+R KEYPAD

METAL KEYS

薄膜按鍵

MEMBRANE SWITCH

薄膜按鍵結構 :

主要結構分為Overlay、Tactile Spacer、Upper Switch、Spacer、Lower Switch、Back Adhesion 與 Connector 等,也可增加 Metal Dome,LED 或電阻,電容等 SMT 零件如左圖說明。

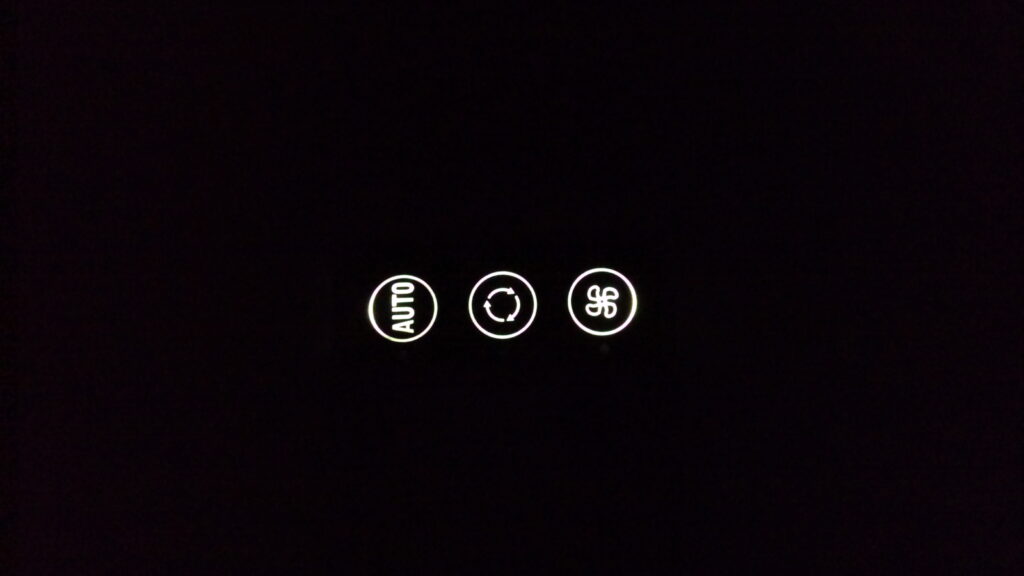

薄膜按鍵背光應用

若按鍵有背光的需求,薄膜按鍵可以提供不同的背光方式達到此目的。例如:

LED 正發光, LED 側發光,導光片, EL 發光片,光纖導光條等.配合客戶獨特的需求來進行深度客製化的發光應用。

按鍵背光的應用很廣,包括遙控器,一般家電,工業用人機介面或是醫院等,光線昏暗環境時,可提供背光,讓使用者能夠辨識按鍵的功能,甚至現今流行的電競鍵盤也是薄膜按鍵的應用之一。

薄膜按鍵防水需求

薄膜按鍵能夠做到防水防塵的結構.搭配不同的黏膠,將各結構加以黏貼,就能達到防水的需求。

IP62 是最基本的防護,若要達到 IP65 以上的防護就須配合特殊的結構與黏膠來達成此目的。

按鍵

KEYPAD

橡膠按鍵,金屬按鍵, P+R 按鍵(PLASTIC+RUBBER) 都是我們可以服務的範圍.模組化的結構更是我們的強項.按鍵搭配薄膜鍵, FPC 或 PCB 等,再配合射出外殼與基座等,客戶只需一次訂購,即可達到分開採購及組裝的目的,大大減少公司人力及採購費用。

按鍵背光需求

由於按鍵結構整體設計,背光可輕易整合模組結構內,搭配按鍵噴塗,雷雕,或是IMD KEY印刷的方式來達成符號透光的目的。

橡膠按鍵

成本相對便宜,外觀可噴漆,印刷,或雷雕,按壓彈力可以直接以橡膠按鍵結構來設計,導通的部分

直接以碳粒 (Contact pill) 製作,不須額外彈片結構,但 SILICON RUBBER 因使用環境的影響,造成出油或汙染則容易使的按鍵功能失常,則需要其他結構設計來避免。

IMD P+R

按鍵塑膠與 RUBBER 噴漆製程因環保問題,會使的噴漆成本越來越高,此時 IMD KEY 會是一個很好的選擇。

外觀直接印刷於薄膜上,再經射出製程將外觀處理直接與射出結合,不但解決了外觀耐磨的問題,人體不會與油墨接觸,更縮短了噴漆雷雕時間過長的問題。

金屬按鍵

金屬蝕刻,打凸再配合印刷等製程,達到按鍵長時間使用不損壞的目的,常見於AMT或其他機器設備上。