In Mold Decoration – IMD

IMD, IMF, IMR, IN-MOLD DECORATION, TAIWAN

Honlex has been involved in the injection molding industry for nearly 15 years, offering a one-stop production process that includes material selection, ink printing, hot or vacuum forming, mold design, injection molding, 3D trimming, final appearance inspection, and packaging. By maintaining complete control over the entire process, we can ensure high yields and provide customers with satisfactory quality and delivery.

INJECTION MOLDING, IN-MOLD DECORATION, STRUCTURAL INTRODUCTION

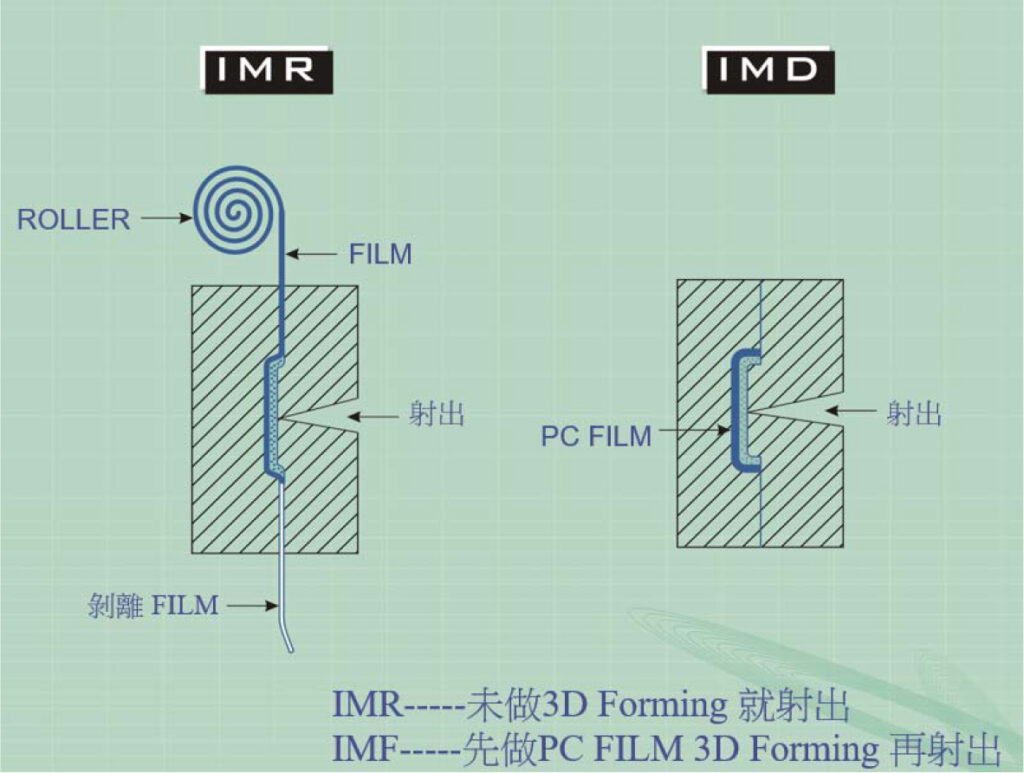

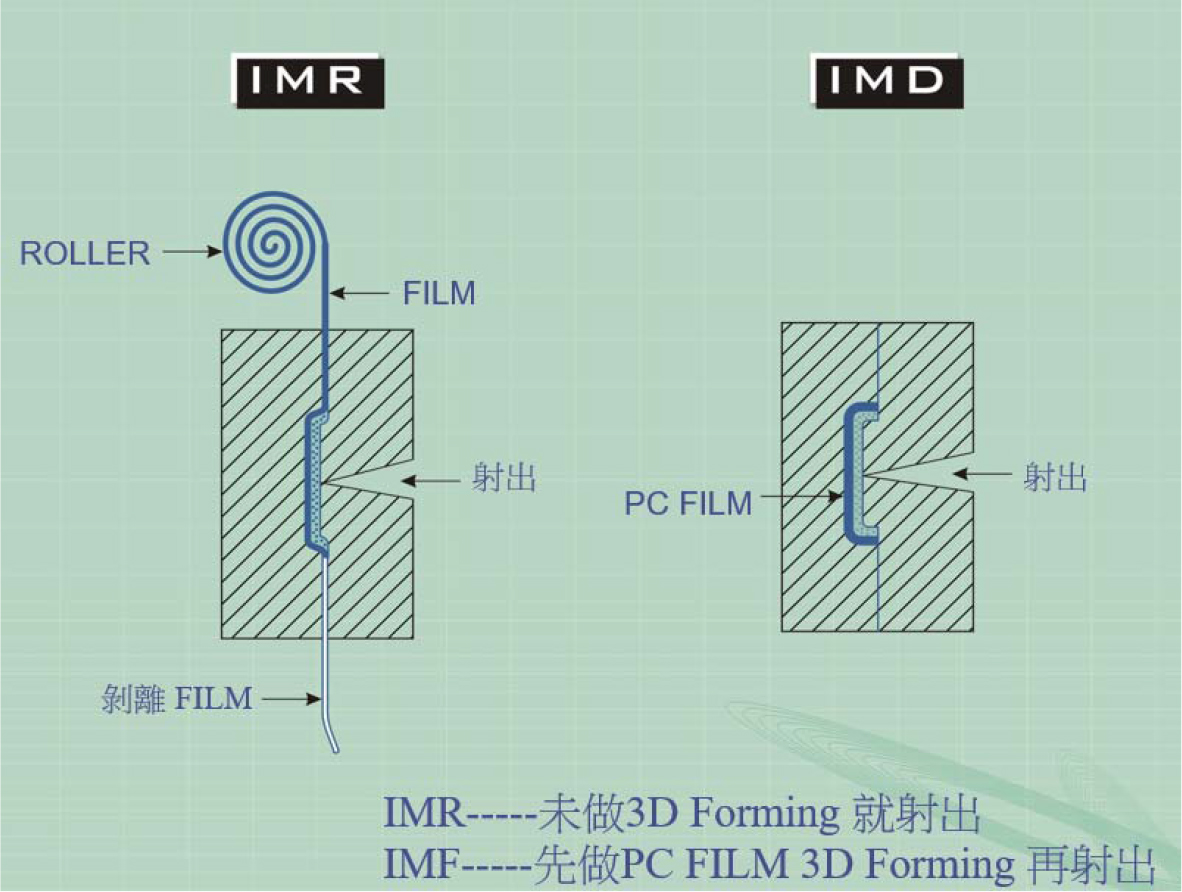

Introduction to In-Mold Injection Molding: The basic principle is to print the thin film, then forming and cutting it into a single mold , and finally embed it into the injection mold for injection molding, as shown in the figure on the left.

APPLICATIONS OF IN-MOLD DECORATION

Due to the capability of In-Mold Decoration to achieve various appearance requirements through printing, the number of mold disassemblies can be reduced. For example, windows can be molded together with the outer shell, and only printing on the lattice is needed to achieve the purpose of windows, without requiring two sets of molds for windows and upper shells. Since the mold does not need to be disassembled, it is particularly suitable for the use of waterproof and dustproof outer shells, which can be combined with touch modules and used in humid environments such as bathroom and water dispenser equipment.

MATERIALS USED IN IN-MOLD DECORATION

The success of the IMD process is influenced by the stretchability of the film, print adhesion, and flowability of the injection material. Therefore, before formal mold opening, it is necessary to determine which materials to use to achieve our set goals. Materials such as PC, PET film, heat-resistant ink, high flowability injection materials like PC, ABS, PMMA, and PC+ABS are all options we would choose.

模內射出 / 模內裝飾

IMD / IMF / IMR

模內射出結構介紹,基本原理為薄膜印刷後,經過熱壓成型,衝切成單模後,再埋入射出模具裡進行射出成形,如左圖說明。

模內射出應用範圍

由於模內射出可應用印刷方式來達到不同的外觀需求,故可以減少模具拆解數量,如視窗可與外殼一起射出,僅印刷簍空即可達到視窗的目的,而不須要拆成視窗與上殼兩套模具.由於模具不須拆解,故特別適合用於防水防塵的外殼使用,搭配觸控模組,可使用於衛浴設備,飲水機設備等潮濕的環境。

模內射出使用材料

不管是薄膜拉伸性,印刷接著性,射出料的流動性皆影響著 IMD製程的成功與否.故正式開模前須確認使用何種材料來達到我們設定的目標。PC,PET 薄膜,耐高溫油墨,高流動性的射出 PC,ABS,PMMA,PC+ABS 等,都是我們會選擇的材料。

Type to search